PMP Assignment 3.2 - Lean Project Management Pt.1

Post WWII, Japan want to run the manufacture units with minimum cost. Running cost become more, especially with Toyota car manufacturing unit. Taichi Ohno, Japanese Engineer and business man brought the concept of TPS (Toyota production system) originally called as JIT (Just in time). Concept of TPS is "Mudi", "Mura", "Muri". Later these concept introduced in US based motor companies & familiarized with Lean concept.

The machines that changed the world written by James Womak & Daniel Jones, changed the production based industries' style of work and acknowledging the concepts of Lean.

Techniques involved in this TPS are Kaizen, Obeya, Gemba, Poka yoke can be explained in this chapter. Other than that charts like, fish-bone diagram, KANBAN, Fault tree analysis, Reverse fault tree analysis can be explained in other chapters. Deming's cycle already mentioned in one of the article, http://www.jonnynow.com/2014/08/pdca-demings-cycle.html

Lean project management is a set of ideas, where with a less wastage can provide more value.

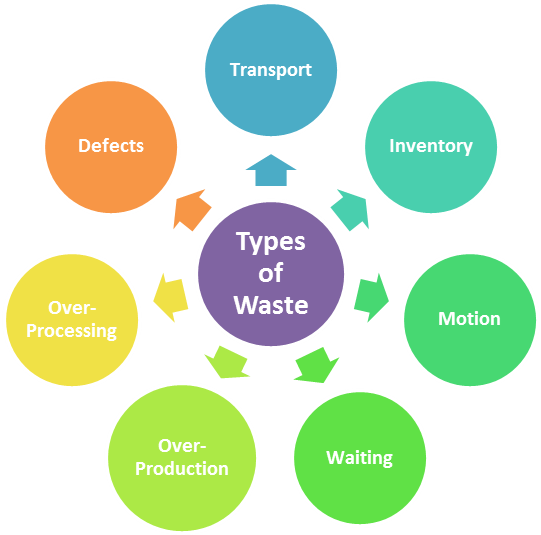

MUDA - Wastefulness

MURI - Beyond one's power

Overburden or assigning the tasks to Men and machinery more than 100% may result with impact to business. Machines can be optimized with their performance, employees efforts can be safeguarded by the safety measures, through process designs and defining the work standards.

MURA - Unevenness

You can assume the Demand and supply here, where the demand available with the customer, production should be able to complete the demand. Over production or Under production should be monitored and rectified with the techniques. Also creating the openness in Supply chain, change product design and creating standard for employees included in MURA.

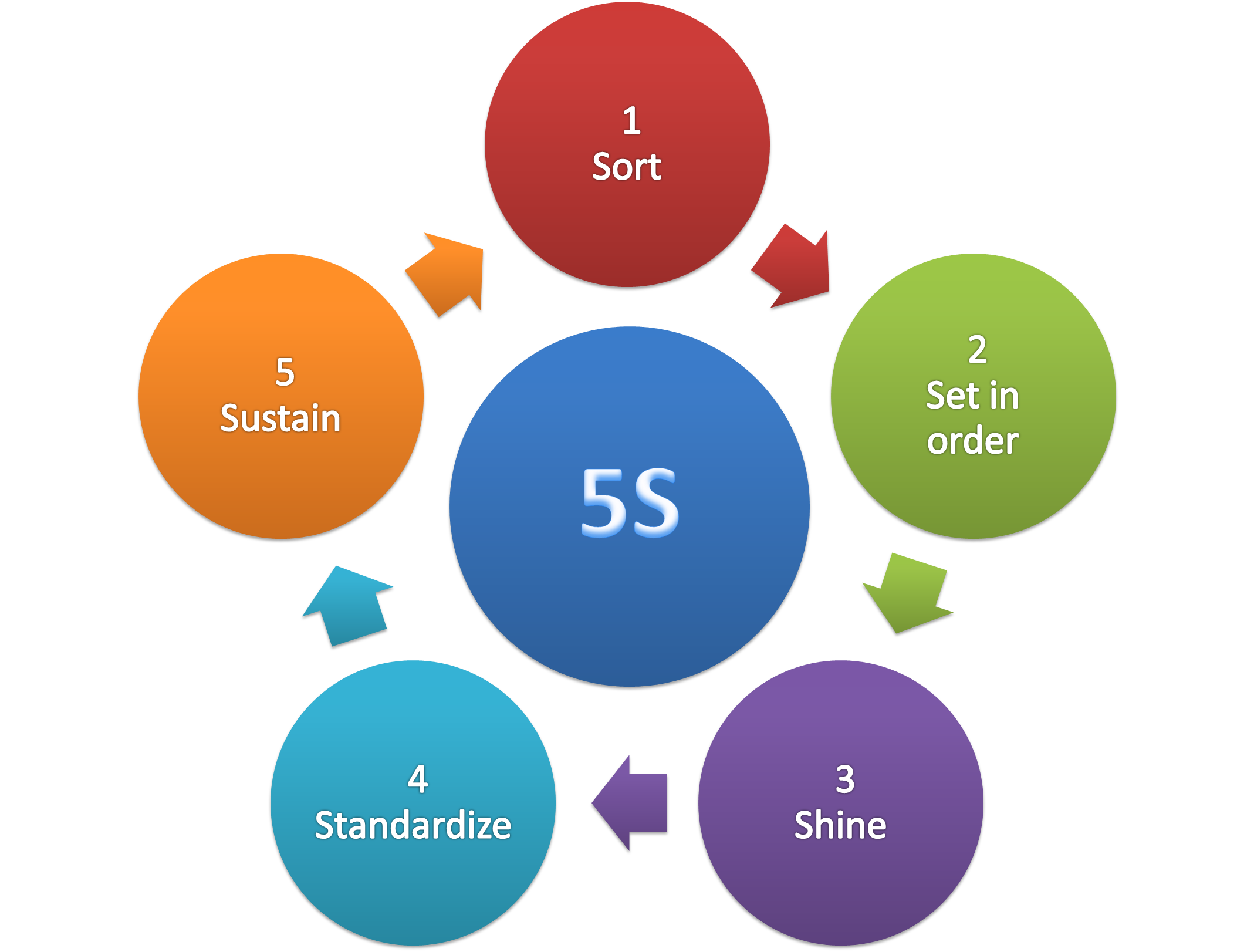

Kaizen - 5S

Kaizen change for better. 5S elements are called as continual improvement in process.

to be continued...

10 comments

When you are PMP Certified it tells businesses, customers and partners that you have a set up skill in overseeing ventures. ExcelR PMP Certification

Pretty good post. I just stumbled upon your blog and wanted to say that I have really enjoyed reading your blog posts. Any way I’ll be subscribing to your feed and I hope you post again soon.

data science course in malaysia

best tableau training

data analytics course malaysia

360DigiTMG

Enjoyed reading this article throughout.Nice post! Digital Marketing is the trendy course right now and is going to be in

a great demand in near future as jobs for this domain will be sky rocketted.To be on par with the current trend we have to

gain complete knowledge about the subject. For the complete course online

360Digitmg Digital Marketing Course

Enjoyed reading this article throughout.Nice post! Digital Marketing is the trendy course right now and is going to be in

a great demand in near future as jobs for this domain will be sky rocketted.To be on par with the current trend we have to

gain complete knowledge about the subject. For the complete course online

360Digitmg Digital Marketing Course

This is a wonderful article, Given so much info in it, These type of articles keeps the user's

interest in the website, and keep on sharing more ... good luck.

360digitmg Machine learning course in hyderabad

Excellent Blog! I would like to thank for the efforts you have made in writing this post. I am hoping the same best work from you in the future as well. I wanted to thank you for this websites! Thanks for sharing. Great websites!

360digitmg-Data-science - course-in -chennai

I wanted to thank you for this website! Thanks for sharing. Great websites!

pmp certification in hyderabad

You may remark on the request arrangement of the blog. You should talk it's stunning. Your blog review would expand your guests. I was satisfied to discover this site.I needed to thank you for this extraordinary read!!artificial intelligence course in delhi

Thanks for the information about Blogspot very informative for everyone

data science course gurgaon

Thanks for sharing nice information....

data science courses in aurangabad

Post a Comment