PMP Assignment 3.3 - KANBAN

KANBAN - Make it Happen

KANBAN in tamil there is a word called Kaanbaen, its to say I will see. In same way KANBAN is to visualize, what we are going to do in projects. Toyota introduced KANBAN to create the cards and attaching the card in a set, which contains model of the car, equipments, tools and techniques which required to use., while conveyor travels to next person, he can understand what he needs to do. This requires a training to understand what process and to understand the card. Process is to understand, what are the tools and techniques involved in a certain card. Card coloring, how to read a card, a supervisor or a trainer to teach the employee how to read and understand a color coding and grab the information from it. Also one can segregate, the job where it is getting struck with either it is To do, Doing or Done.

KANBAN in supermarket:

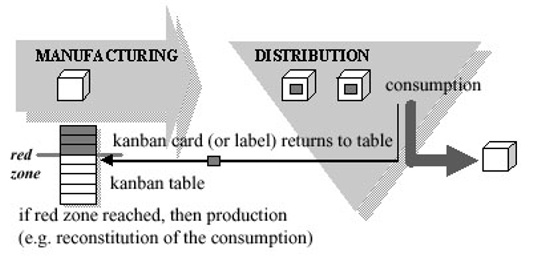

Often supermarkets says that they are inventory less, so often they tend to lose the customer. With KANBAN method they can know which is the fast moving product and when to order such items. Lean method included with KANBAN is to understand the curves of demand and supply often and to fill the gaps whenever it is required. Please see the below video, to understand more,

Above one is a withdrawal KANBAN method, but that is the perfect example which suitable for supermarket operations.

KANBAN in factories

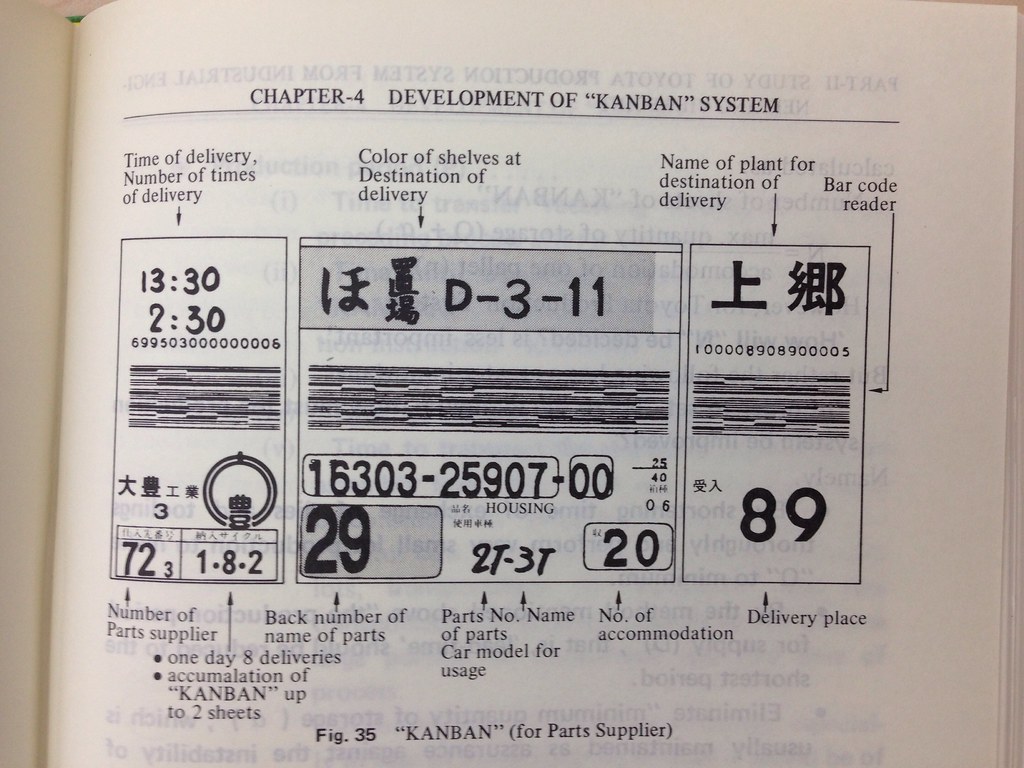

KANBAN initially introduced in Toyota Factory, in part of Just In time. To improve the efficiency of production and aligned with the market changes, Taichi Ohno's methodology of KANBAN introduced in Toyota factory, to improve the process also employees to understand the changes in the market.

This factory introduced KANBAN card which contains the information about the car model or the project they are working,

KANBAN in Information Technology

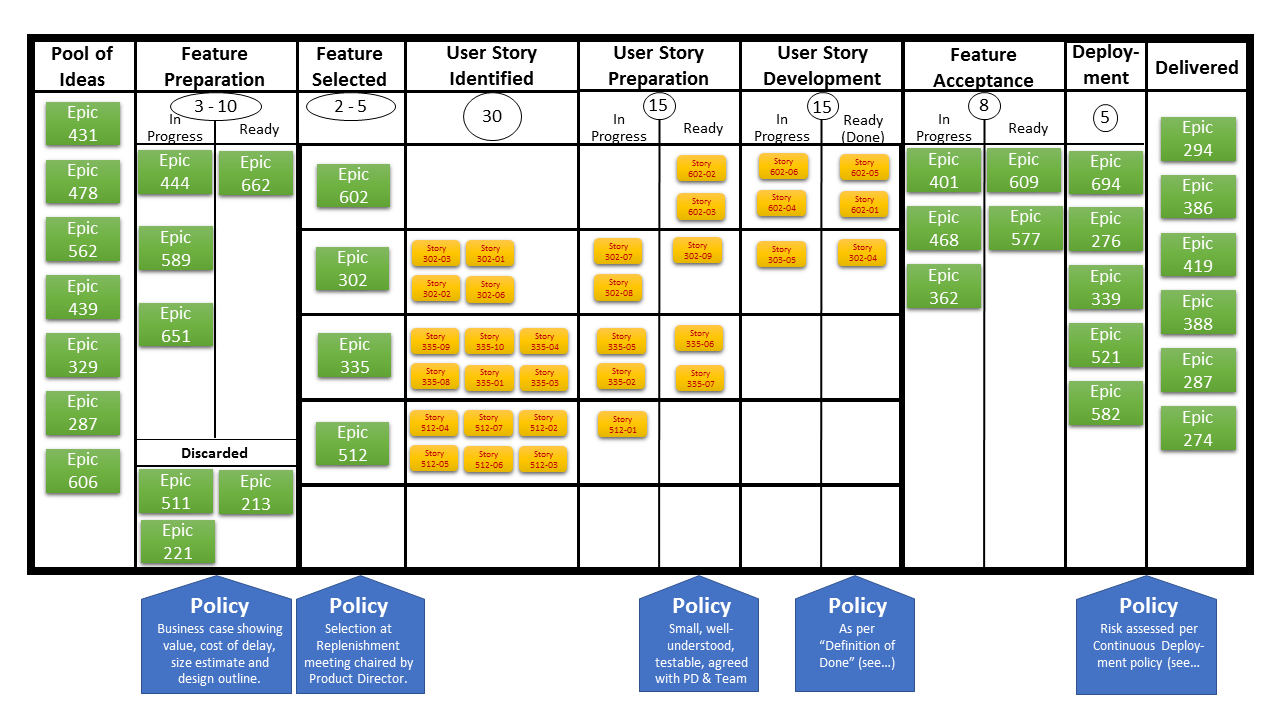

E-Kanban created to minimize the faults in manual KANBAN. But KANBAN cards used in information technology, is different from usage of E-KANBAN. After Lean methodology included in KANBAN, each step has been customized and included in KANBAN. KANBAN is largely customized,

From developing software to creating the application, KANBAN is customized as per the organization or team's requirement. Business Case to solutions one can use KANBAN methodology. Above scenario shows, how the ideas are generated and feature started, story board creation, feature acceptance and deployment.

Here if you see, Ideas, Features can be constant, Ideas to features to story board may vary also one can include more data into that, which can be relevant from time to time. At times, requirements and features may be vary, we may subject to change or alter the story board. KANBAN is fully customized, accustomed to give the path for the changes.

11 comments

It is an exhaustive confirmation program on the off chance that you are in the matter of overseeing tasks and searching for approaches to run extends all the more productively.ExcelR PMP Certification

Attend The PMP Certification in Abu Dhabi From ExcelR. Practical PMP Certification in Abu Dhabi Sessions With Assured Placement Support From Experienced Faculty. ExcelR Offers The PMP Certification in Abu Dhabi.

ExcelR PMP Certification in Abu Dhabi

Excellent Blog! I would like to thank for the efforts you have made in writing this post. I am hoping the same best work from you in the future as well. I wanted to thank you for this websites! Thanks for sharing. Great websites!

360DigiTMG data analytics courses in hyderabad

Hello, I have browsed most of your posts. This post is probably where I got the most useful information for my research. Thanks for posting, we can see more on this. Are you aware of any other websites on this subject.

<a href="https://360digitmg.com/india/professional-certification-in-business-analytics “>business analytics certification</a>

I would like to thank you for the efforts you have made in writing this post.

pmp certification in hyderabad

Thank you for this wondrous post, I am happy I watched this site on yippee.

360digitmg data science course in india

Through this post, I realize that your great information in playing with all the pieces was exceptionally useful. I advise this is the primary spot where I discover issues I've been scanning for. You have a smart yet alluring method of composing.

data science course in delhi

thanks for share

data scientist online course

Excellent Blog! I would like to thank for the efforts you have made in writing this post. I am hoping the same best work from you in the future as well. I wanted to thank you for this websites! Thanks for sharing. Great websites!

data science course in aurangabad

Such a very useful article. Very interesting to read this article.I would like to thank you for the efforts you had made for writing this awesome article.

artificial intelligence courses aurangabad

cool stuff you have and you keep overhaul every one of us

artificial intelligence training in chennai

Post a Comment